|

|

|

|

|

|

|

|

|

Boat sewing techniques overview

Boats being sewn in the inner Finnish area,

from woodcut by Olaus Magnus (1539, 1555).

Boats being sewn in the inner Finnish area,

from woodcut by Olaus Magnus (1539, 1555).

|

A Saami boatbuilder from the title page of Schefferus book

Lapponia (1674).

A Saami boatbuilder from the title page of Schefferus book

Lapponia (1674).

|

People started to build wooden boats in the stone age, long before they developed the technology of melting metals out of ore; and for centuries after metals became known, the nails, rivets, and other metal fastenings remained quite an expensive luxury. So, along with big and rich ships with metal fastenings, such as Viking ships with their iron rivets, there existed a lot of small boats, belonging to poor fishermen and peasants, who could not afford iron. (Actually, in some rural areas of northern Russia nails were deficient even in 19-20th century). These boats were to be built in some other way, using either treenails or sewing techniques. The later way was the most common, since treenails can only hold when the planks are thick enough, which is not the case with small light boats. Apparently, sewing was used in most parts of the world -- in Northern Europe, in Indian Ocean area, the "Mahasagar boats" firm, in Mangalore, India, can custom-build a tradition�l stitched canoe. See also boatbuilding in Goa, in ancient Rome (boats, sewn with hemp twines), in Polynesia, etc.

For the sewing material roots of coniferous trees (spruce or pine) were most commonly taken; they were the cheapest and most available stuff -- in a dark coniferous forest soil is so loose and grasless that one can easily pick the roots up with bare hands, using only a knife to cut them. Broad leaf tree roots (such as birch roots) were also taken sometimes, but they are probably harder to obtain, the soil in a birch forest usually has a firm layer or grassy turf. Apart from spruce, some other species roots were used, like juniper, pine, birch, etc., as well as twisted slender shoots off the same juniper, birch, hazel, willow, or young spruce's stems. Other sewing materials known from archaeological finds are hemp and woolen twines, linden bast ropes, reindeer sinews and horsehair strands.

Youngest sewn boat finds in Europe were made in Ferriby, England, 1300 BC,and in Hjortspring bog in Denmark, the boat was dated for 3rd century BC.

Many finds are attributed to the Viking and

Middle ages, when sewing techniques coexisted with metal nails and rivets;

even in a same ship sometimes both ways were present, expensive iron was

usually used in toughest and most critical places;

a kind of similar technique, when bottom parts of ribs were lashed to the

planking by means of spruce roots, was implemented in famous Gokstad and Oseberg

ships.

Often sewing was used as a repair technique for cracks and clefts in

dugout boats.

This way of shipbuilding flourished in 16-17th centuries in NW Russia, the entire

Pomor fleet on White and Barents seas was withy-sewn. Some of the Pomor "koches"

were as big as 100 tons displacement, they could reach Shpitzbergen (which bore

Russian name of Grumant those days) safely, and ply another important merchant

route -- the "Mangazeja route" from Archangelsk and Holmogory along the Siberian

Arctic coast to the river Taz mouth. Archaeological excavations revealed a plenty

of sewn ship wood both on Shpitzbergen and ancient Mangazeja site, but unfortunately

it was mostly re-utilized for cabin building or firewood, -- a usual custom of the

North. Now it is quite hard to reconstruct a Pomor "koch" design and lines reliably.

Apart from "koches", pomors had many other vessel types, such as "kochmara", "lodja",

"shitik", "soima", "shnjaka", "karbas", "ranshina", etc. A well preserved

sewn shnjaka from Murmansk coast is exhibited in Oslo maritime museum, it was

probably built in 1905. Her length is about 11.8 meters, width 2.7 meters, -- rather

big seagoing ship, with just traditional lines and design of Russian North,(reminiscent

of a smaller

Sewn vessels existed on Baltic as well. One of the archaeological ship finds occurred in 1896 in Stockholm, when building a house on Skeppargatan str. 4. The ship was impressively large -- over 20 meters length, the preserved keel parts are ~40x40 cm in crossection, clinker planking 5-7cm thick slabs, roughly carved with axe out of split pine logs halves. Sewing spruce withies approx. 20mm thick. Dated around 1700, -- it is not unprobable, that this was one of the ships built by Russian peasants (unfamiliar with Western and Dutch shipbuilding) for Peter the Great's campaign on Baltic. It could have been captured by Swedes and brought to Stockholm.

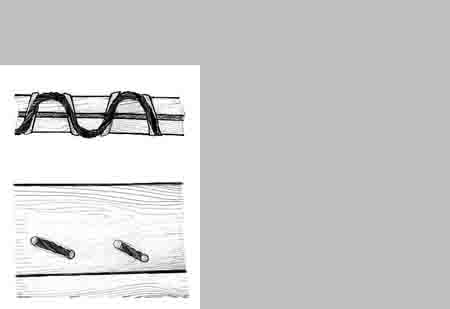

Full scale image (20Kb) Sewing technique common in Russian Pomor area and on Baltic, so called

"continuous" seam. Stitches were laid just like in a simple seam with thread

and needle. See also: |

The simple 'lashed' sewing, Finnish nide ("Merkijärvi") type, Keuru No. 9 (after Korhonen, 1982a; redrawn from Hirsjärvi, 1937). In Finland there existed another type of sewing technique, christened

"Merkijärvi" type, or nide/näst method, when a spruce root was just pulled several times

through one pair of holes, but did not go to adjacent holes, making

rather distant separate fastenings. See also: |

Sewing arrangement of the Hjortspring joints

(Smolarek, 1963).

Sewing arrangement of the Hjortspring joints

(Smolarek, 1963).The sewing material not preserved, but the the stitching technique could be judged of by well preserved imprints on the caulking stuff (resin, linseed oil, ox tallow). |

|

|

|

|

|

|

|

|

|

last update: February 2006 report problems with this page to ![]()