|

|

|

|

|

|

|

|

|

Ripping logs into planks by hand rip-saw

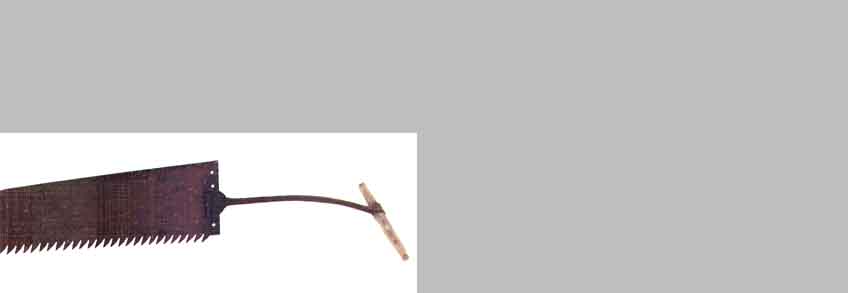

Full scale image (53Kb) Ripping logs into planks. August 2001. Since the purpose of our archaeological experiment was to reproduce the entire technological chain, all planks were done manually, by means of men driven rip-saw. This technique originated in 13-14 centuries in civilized European centers, and existed almost until present day, yet in 1950-60ies it was implemented in remote villages and kolhozes in Soviet Union. During most of this time the technique coexisted with more progressive water driven lumber mills, later powered by steam and electricity. On the other hand, primitive way of carving planks with axe out of wedge split logs also existed during most of the period (this way also was experimentally reproduced, see: boat reconstruction on Vodlozero , at Fotevikens museum, Tuna i Badelunda boat.) In any case, many old village people remember sawing planks this way in their youth, they could give us a competent advice, and some surviving rip-saws were found almost in working condition. We only had to master this craft in practice. A log has to be rolled up onto two high sawhorses, and first central cut has to be marked on it (both from above and from beneath) by means of coaled string and plummets. Sawing starts from one end and proceeds till sawhorse was reached; then two adjacent cuts are to be marked on both sides of the central cut, and sawn up to the sawhorse, too. When all cuts are done from the log end to the sawhorse, the log has to be moved along so as for the cuts to appear from the other side of the sawhorse. Now the saw can be inserted into a cut to proceed with sawing between sawhorses. The handle at the rip-saw's lower end is quick-release, it has to be taken away to insert the saw into a cut. The log has to be moved for a second time when second sawhorse was reached; then sawing goes to the other log end, and it falls apart into planks. |

|

Full scale image (18Kb)

Full scale image (18Kb)At least 20 planks 4-8 meters long and very wide - 35-45 cm. were needed for the ship. (Ruler on the picture is 1 meter long). These could be obtained by sawing 3 logs 7-8 meters long into 8 or 9 planks each; total cut length was approx. 200 meters. It sufficed 5 working days to rip one log, the overall time spent on plank sawing did not exceed 3 weeks for two people, who were actually newcomers in this craft. So the productivity was found even higher then expected, and compared to the overall labor input of the ship building (12-15 working months/person), quite acceptable. The planks were smooth and even enough, nearly of the same quality as average lumber mill wares. November 2001. |

|

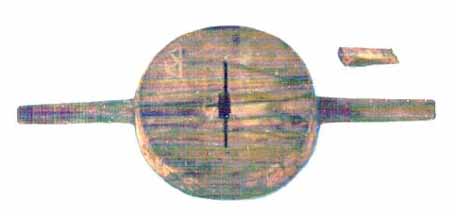

Full scale image (18Kb) Upper handle of the rip-saw. |

|

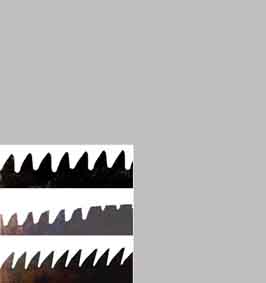

Full scale image (29Kb) Teeth shape. The cutting principle is generally the same for all saws that work along wood grains - lumber mill saws, circular saws, or motor saw chains. Tooth has a shape of a chisel, we sharpened them with a small round file like a motor saw chain (picture to the right). It seems this was originally done with flat or triangular file, so teeth had peculiar "hooks" at their ends -- picture above. Teeth must be set apart just like with usual crosswise saw, but they also must be twisted in order to cut the kerf's walls with their edges, instead of rubbing along them with their flat sides. After certain number of sharpenings teeth shape would deteriorate, and the saw would reqire punching of new set of teeth in a blacksmith . (Same with gas saw chains - they become bad after a number of sharpenigs). Old teeth were sometimes left at a saw's end, - one can see these on the picture above (middle). |

Lower quick-release saw handle -- s.c. "mylka", the word can be translated as "soap thing" --

probably because it used to become soapy with hand sweat. It goes with its slot onto saw's

lower end, fixed with the wooden wedge.

Lower quick-release saw handle -- s.c. "mylka", the word can be translated as "soap thing" --

probably because it used to become soapy with hand sweat. It goes with its slot onto saw's

lower end, fixed with the wooden wedge.

|

|

|

Full scale image (93Kb) Ripping logs into planks in Turchasovo village, Onega, Archangelsk province, early XX century. Photo: courtesy Onega local lore museum. |

|

Full scale image(130Kb) Sawing logs at Kuzminskoe village on Oka river. Color photo taken in year 1912. From Prokudin-Gorskii collection in US Congress library. (color separation achieved by taking 3 black-and-white frames of the same scene trough different color filters) |

|

|

|

|

|

|

|

|

|

|

last update: February 2006 report problems with this page to ![]()